In certain situations, you may need to grab your car jack when your vehicle experiences a problem or runs into trouble. One common example is a flat tire.

A car jack is a simple yet invaluable tool for raising a vehicle off the ground. Typically made of sturdy metal, it provides the mechanical advantage needed to lift a car, allowing access to its underside for tasks like changing a flat tire, conducting routine maintenance, or making repairs.

There are different types of jacks, such as scissor jacks, hydraulic jacks, and bottle jacks, each with its method of operation. If you are unfamiliar with the concept of “How to use a car jack” then in this article you will find information on how to use a car jack, how to jack up a car, and the correct jacking points.

Table of Contents

How to jack up a car?

Whenever a situation arises where you need to learn how to change a flat tire, the first thing you need to know is how to jack up a car.

Car Jacking Tool Requirements

Before you dive into the process of jacking your car, you need the right tools to get the job done.

You will need tools such as:

- Car Jack: The type of car jack you use will depend on your vehicle and the task at hand. Common types include scissor jacks, hydraulic floor jacks, bottle jacks, and trolley jacks.

- Vehicle Owner’s Manual: Your vehicle’s owner’s manual provides specific instructions, including the location of manufacturer-recommended jacking points.

- Safety Equipment: Safety should always come first. Safety glasses and gloves are essential for protecting your eyes and hands during the process.

Step-by-step guide on how to jack up a car

- Choose a Safe Location: Park your vehicle on a level, solid surface. Engage the parking brake to prevent rolling. Ensure you’re safely away from moving traffic.

- Locate the Jack Points: Consult your vehicle’s owner’s manual to find the manufacturer-recommended jack points. These are usually marked by notches or reinforced areas along the frame.

- Position the Wheel Chock: Place the wheel chock against one of the tires on the opposite side of the car from the one you plan to lift. This prevents the vehicle from rolling while you’re lifting it.

- Prepare the Jack:Place the jack on a stable and level surface, aligning it with the chosen jack point on the vehicle. Make sure the jack’s saddle (the part that contacts the vehicle) is positioned correctly.

- Operate the Jack:Depending on your jack type, follow the manufacturer’s instructions. For most jacks, use the provided handle or a crank to raise the vehicle. Typically, turning clockwise raises the car.

- Lift the Vehicle:Gradually raise the vehicle, keeping an eye on the process. Do not rush, and never place any body part under the vehicle while it’s lifted.

- Perform that tasks you need: If you need to do tasks that require you to go place any of your body parts under the vehicle, it is highly recommended to put jack stands to the jack points of your vehice. These serve as additional pillars of security, in case your car jack fails for some reason.

- Lower the Vehicle: Carefully lower the vehicle by reversing the operation of the jack. Turn the jack handle or crank counterclockwise to lower the vehicle until it rests securely on the ground.

Safety Tips:

- Always consult your vehicle’s owner’s manual for specific instructions and recommended jacking points.

- Never place any part of your body under the vehicle when it’s raised on the jack.

- If you need to work under the vehicle for an extended period, use a jack stand for added safety.

- Ensure the jack is on a solid, level surface to prevent tipping or sinking into soft ground.

- Exercise caution when working with the jack, and if you’re unsure, seek professional help or guidance. Safety should always be your top priority.

Where to jack up a car (jacking points)?

Selecting the proper jacking points when lifting a car is an essential step to maintain safety and protect your vehicle from harm.

Car manufacturers carefully designate recommended jacking points, and these locations are indicated in your car’s owner’s manual. These spots are strategically chosen for their structural integrity and stability, ensuring that the vehicle remains secure during the lifting process.

Manufacturer-recommended points are typically situated on the vehicle’s frame, away from vulnerable components such as suspension parts or delicate undercarriage.

To identify suitable jacking points when you don’t have access to your owner’s manual, there are some general guidelines you can follow:

- One of the most reliable indicators for a secure jacking point is the presence of reinforced metal sections on the vehicle’s frame. These parts are designed to withstand the stress of lifting and are usually situated along the sides of the vehicle.

- Avoid jacking up your car in areas with visible rust. Rust can weaken the structural integrity of the metal, making it unsafe for lifting. Opt for solid, rust-free regions to ensure stability.

- When using a jack, make sure that the jack’s saddle (the part that comes into contact with the vehicle) has full contact with the jacking point. This maximizes stability and minimizes the risk of slippage.

- It’s advisable to use quality jack stands in addition to the hydraulic jack, particularly if you’ll be working under the vehicle for an extended period. Jack stands to provide an extra layer of support, enhancing safety and preventing accidents in case the jack fails.

In all instances, prioritize safety above all else. The correct jacking points play a pivotal role in establishing a safe working environment while lifting your vehicle. Following these guidelines, or consulting your owner’s manual, will help you safeguard both yourself and your vehicle during maintenance or repair tasks.

Always double-check your chosen jacking points and be cautious to prevent accidents and expensive damage.

Common Mistakes to Avoid

While using a car jack, avoid these common mistakes for safety and vehicle protection:

- Not Following the Owner’s Manual: Overlooking the guidance provided in your vehicle’s owner’s manual, including specific jacking points, is a significant error. These recommendations are designed to keep you and your car safe during lifting.

- Using an Inappropriate Jack: Using a jack that is not suitable for your vehicle or the specific task at hand can be dangerous. Always choose the right type of jack for your car and the job.

- Failing to Secure the Vehicle: Neglecting to engage the parking brake and use wheel chocks can result in the vehicle rolling when lifted which can lead to accidents and injury.

- Overextending the Jack: Attempting to lift the vehicle too high beyond the jack’s intended capacity can stress the equipment and create instability, risking the car’s balance.

- Working under the Vehicle without Proper Support: When working beneath the vehicle, failure to use jack stands or alternative support mechanisms poses a serious safety hazard. Never rely solely on the jack to keep the car elevated.

- Ignoring Safety Gear: Skipping essential safety gear like gloves and safety glasses can expose you to potential injuries from sharp edges, dirt, or falling debris. Always prioritize personal protective equipment.

- Neglecting Vehicle Weight Limits: Every jack has a weight limit that should never be exceeded. Going beyond this limit is not only unsafe but can also cause damage to the jack itself, creating an additional hazard.

When you use a car jack, exercise extreme care. Prioritize safety and follow the correct steps to lift your vehicle securely. This ensures the well-being of both you and your vehicle, preventing accidents and damage during the process.

Types of Car Jacks

Choosing the right car jack depends on your specific needs, vehicle type, and the level of convenience you seek. Each type has its own set of advantages and disadvantages.

Scissor Jacks

Illustration: Scissor Jack

Operation:

- Lifting: Scissor jacks are manually operated and are often supplied with a detachable handle. Insert the handle into the provided socket and turn clockwise to lift the vehicle.

- Lowering: To lower the vehicle, turn the handle counterclockwise slowly, ensuring a controlled descent.

Advantages:

- Compact and lightweight, making them portable and easy to store.

- Suitable for emergency tire changes.

Disadvantages:

- Require more physical effort for lifting.

- Limited weight capacity compared to other types

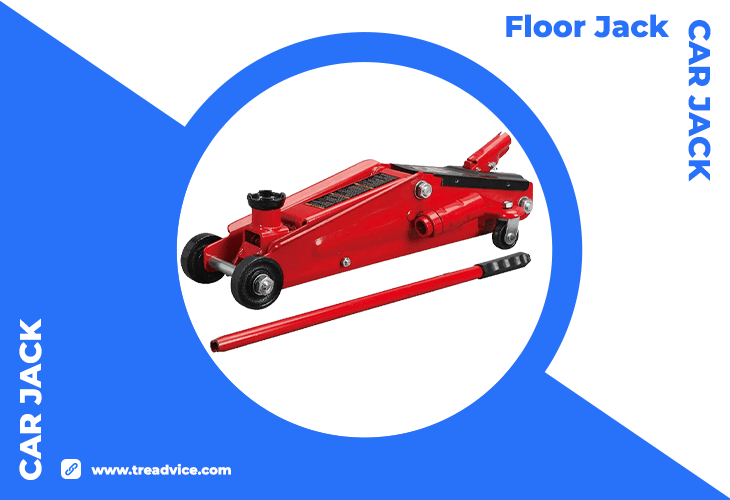

Hydraulic Floor Jacks

Illustration: Hydraulic Floor Jack

- Operation:

- Lifting: Pump the handle to build hydraulic pressure, causing the jack to raise the vehicle.

- Lowering: Open the release valve slowly to lower the vehicle smoothly.

Advantages:

- Quick and easy to use, requiring less physical effort.

- Higher weight capacity than scissor jacks.

Disadvantages:

- Bulkier and heavier than scissor jacks, making them less portable.

- Slightly more complex maintenance.

Bottle Jacks

Illustration: Bottle Jack

Operation:

- Lifting: Pump the handle to raise a piston, lifting the vehicle.

- Lowering: Turn the release valve counterclockwise to lower the vehicle gradually.

Advantages:

- Compact design with a high weight capacity.

- Versatile and suitable for various vehicle sizes.

Disadvantages:

- Less stable than some other types.

- Limited lifting height.

Hi-Lift Jacks

Illustration: Hi-Lift Jack

Operation:

- Lifting: Operated by a manual lever, engaging a ratcheting system to lift the vehicle.

- Lowering: Release the lever and turn it counterclockwise to lower the load.

Advantages:

- Ideal for off-road situations and larger vehicles.

- Can be used for lifting, pulling, clamping, and winching.

Disadvantages:

- Bulky and heavier than most other jacks, hence they are not that portable.

- Requires caution and proper usage due to its high lifting capacity.

Frequently Asked Questions (FAQs)

Consider your vehicle’s weight, the intended use (e.g., routine maintenance or emergency situations), and your preferred ease of operation. Hydraulic floor jacks are versatile and user-friendly, while scissor jacks are more compact for occasional use.

Scissor jacks usually have a weight capacity ranging from 1 to 2 tons, suitable for most standard-sized vehicles. However, always check the specific capacity mentioned in the product details.

Typcally, yes. as hydraulic floor jacks are suitable for a wide range of vehicles, from sedans to SUVs. Ensure that the jack’s weight capacity matches or exceeds your vehicle’s weight.

Regularly check for hydraulic fluid leaks, keep the moving parts lubricated, and follow the manufacturer’s maintenance guidelines. Bleed the hydraulic system if necessary.

Yes, bottle jacks typically have a higher weight capacity compared to scissor jacks and are suitable for lifting heavier vehicles. Always adhere to the manufacturer’s specifications and guidelines.

While Hi-Lift Jacks are versatile, they are more commonly used for off-road vehicles and recovery situations. For routine maintenance, hydraulic floor jacks or scissor jacks may be more convenient.

Always use the jack on a level surface, place it on a sturdy part of the vehicle frame, and use appropriate jack stands for added safety. Follow the manufacturer’s instructions for proper usage.

It is not recommended to leave a vehicle lifted with a jack for an extended period. Use jack stands to support the vehicle securely during maintenance to prevent accidents.

Jack stands come in various sizes and weight capacities. Choose stands that match your vehicle’s weight and size. Consider using multiple jack stands for added stability.

Scissor jacks have a compact design and are suitable for lighter vehicles, while bottle jacks are more robust and can lift heavier loads. The choice depends on your vehicle’s weight and your specific needs.

Conclusion

They say lifting weights is the key to a strong body. I say, “Why not lift your car? It’s the best way to get jacked in no time!” 😉

Anyways, now that you’re armed with the know-how of choosing and using different car jacks, you’re ready to tackle basic maintenance tasks like a champ!

Happy jacking!